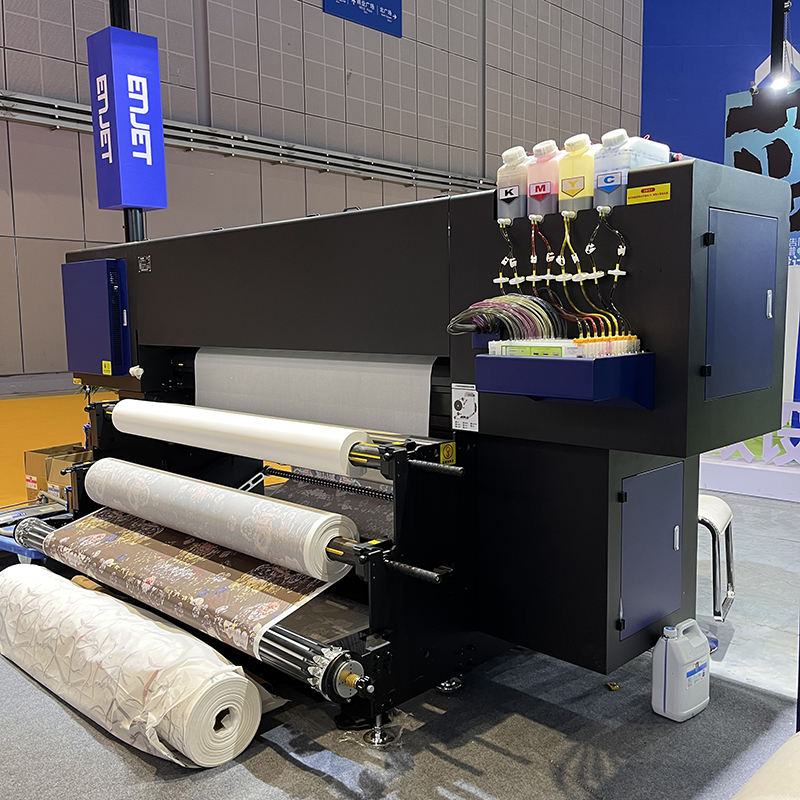

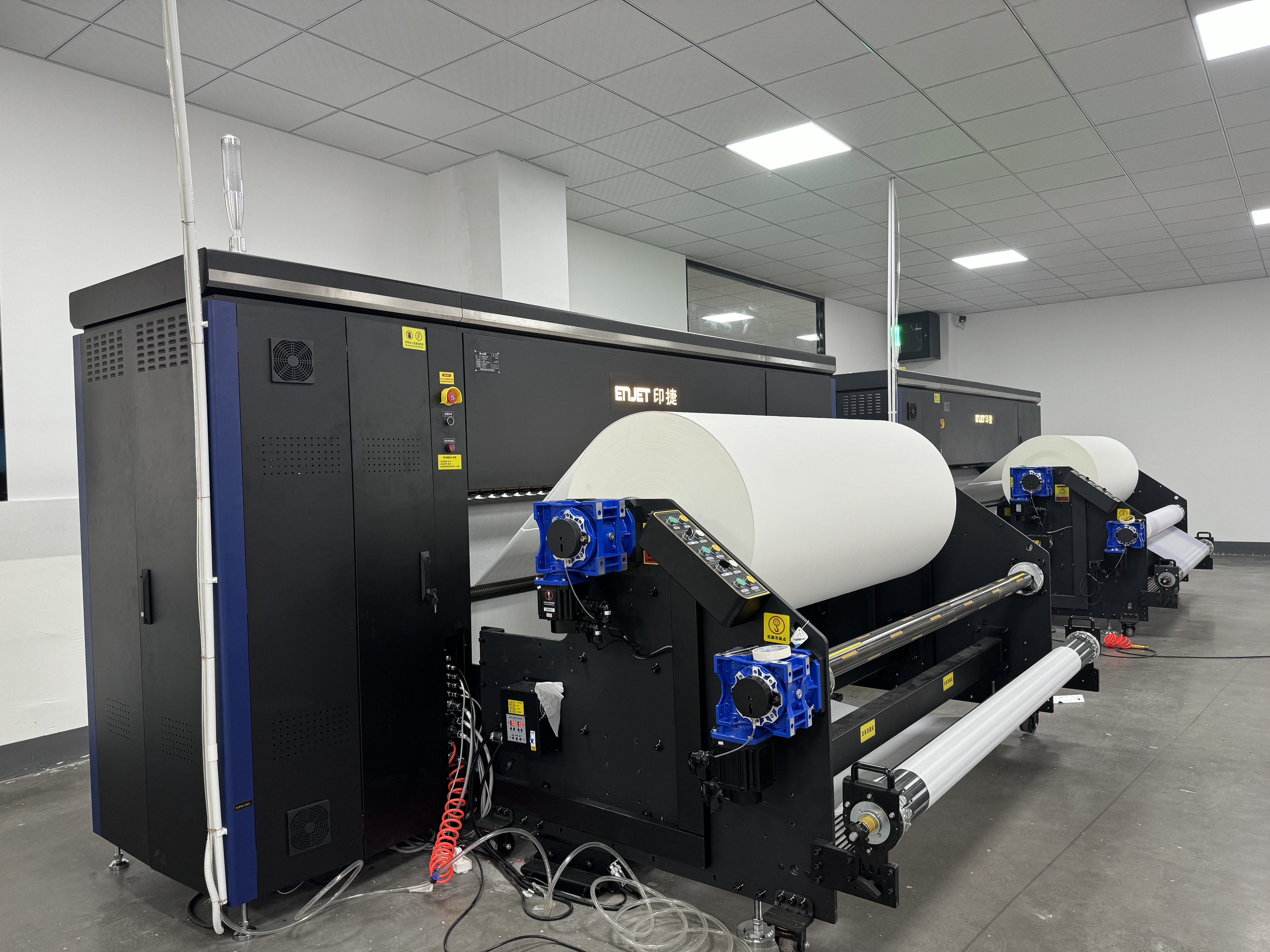

A fabric sublimation printer is a specialized type of printer designed to produce high-quality, durable prints on polyester fabrics and polyester-coated materials. The process involves using heat to transfer dye onto the fabric, resulting in vibrant, long-lasting designs that are embedded into the fibers of the material.

1. What is a fabric Sublimation Printer?

A fabric sublimation printer is a device that uses heat to transfer dye onto materials such as fabric, metal, or plastic. The process involves turning solid dye directly into gas without passing through a liquid state, hence the term “sublimation.” This results in vibrant, durable prints that are ideal for items like custom t-shirts, mugs, phone cases, and more.

2. How a Fabric Sublimation Printer Works

Design Preparation: Create a digital design using graphic design software. This design will be printed onto a special sublimation transfer paper.

Ensure the design is mirrored (reversed) before printing, as it will be transferred onto the fabric in reverse.

Printing the Design: The sublimation printer uses sublimation inks, which are special dyes that turn into gas when heated. The printer prints the design onto the sublimation transfer paper. This paper is specifically designed to hold the dye and release it onto the fabric when heated.

Transferring the Design: Place the printed sublimation transfer paper onto the polyester fabric.

Use a heat tranfer machine to apply high temperature and pressure to the paper and fabric. The typical temperature range is between 350°F to 400°F (177°C to 204°C).

The heat causes the sublimation design to turn into gas, which then permeates the fibers of the polyester fabric.

3. Advantages of Polyester Sublimation Printing Over Traditional Fabric Printing

Polyester sublimation printing is rapidly gaining popularity as a superior alternative to traditional fabric printing methods. Here are several key advantages that highlight why businesses and individuals are making the switch to sublimation printing on polyester:

1. Superior Print Quality

- Vibrant Colors: Sublimation printing infuses dye directly into the polyester fabric, resulting in vibrant, rich colors that are more intense than those produced by traditional printing methods.

- High Resolution: Sublimation printers can achieve high-resolution prints with fine details, making them ideal for intricate designs and photographic images.

2. Durability and Longevity

- Fade Resistance: Unlike traditional prints that sit on top of the fabric, sublimation dye becomes part of the fabric itself. This integration means that prints are resistant to fading even after multiple washes and prolonged exposure to sunlight.

- No Cracking or Peeling: Traditional screen printing and heat transfer methods can crack or peel over time. Sublimation prints maintain their integrity, ensuring a long-lasting, professional appearance.

3. Soft Feel and Comfort

- No Added Layer: Sublimation printing does not add any extra layer on the fabric. This means the printed fabric retains its original softness and breathability, enhancing comfort for the wearer.

- No Hand: The term “no hand” means that there is no noticeable feel of the print on the fabric. This is particularly beneficial for apparel, as it provides a more natural and comfortable feel compared to traditional prints that can feel heavy or stiff.

4. Eco-Friendly Process

- Waterless Printing: Sublimation printing is a dry process that doesn’t require water, unlike traditional dyeing and screen printing methods which consume large amounts of water and generate significant wastewater.

- Reduced Waste: Sublimation printing is a precise process with minimal waste. Excess dye is not used, and there are no additional chemicals needed for setting the dye, reducing the overall environmental impact.

5. Versatility and Flexibility

- Wide Range of Applications: Sublimation printing can be used on a variety of polyester-based materials, including clothing, home textiles, sportswear, and promotional items. This versatility makes it suitable for a broad range of products.

- Small and Large Scale Production: Whether you need a single custom item or a large batch, sublimation printing can handle both with ease. Traditional methods often require significant setup and are more cost-effective only at larger scales.

6. Design Flexibility

- All-Over Printing: Sublimation allows for all-over printing, where the entire surface of the fabric can be printed with a continuous design. This is difficult to achieve with traditional printing methods.

- Unlimited Color Options: Unlike screen printing, which may be limited by the number of colors and complexity of the design, sublimation printing can reproduce an unlimited range of colors and intricate patterns without additional cost or effort.

7. Cost Efficiency

- Lower Setup Costs: For small to medium runs, sublimation printing is more cost-effective due to lower setup costs. Traditional methods often require screens or plates, which can be expensive and time-consuming to create.

- Quick Turnaround: Sublimation printing offers faster production times, as there is no need for lengthy setup processes. This means quicker turnaround times for orders, which is beneficial for businesses responding to market demands.

4. How to Choose a Sublimation Printer

- Printing Speed and Quality: When selecting a sublimation printer, consider the speed and quality of the prints. High-end models offer faster printing speeds and superior image quality, which can be essential for high-volume production.

- Print Size: Choose a printer that can handle the sizes of the items you plan to print. Common sizes include A4 and A3, but there are larger formats available for bigger projects.

- Ink and Consumables Cost: The cost of inks and other consumables can vary significantly. Look for a printer with affordable and readily available supplies to keep your operating costs low.

- Brand and Support: Consider the reputation of the brand and the availability of customer support. Reliable technical support can be invaluable, especially when you’re new to sublimation printing.

5. Sublimation Printing Techniques

- Setup and Installation: Start by setting up your printer according to the manufacturer’s instructions. This typically involves installing the ink cartridges, loading the sublimation paper, and connecting the printer to your computer.

- Design Preparation: Use graphic design software to create your designs. Ensure that the colors are accurately represented and that the design is mirrored before printing, as it will be reversed during the transfer process.

- Printing on Different Materials: Adjust the printer settings based on the material you are printing on. For fabrics, ensure they are made of polyester or have a polyester coating. For hard surfaces, use items specifically designed for sublimation printing, such as coated mugs or metal sheets.

- Transfer Process: Once printed, place the sublimation paper onto the material and use a heat press to transfer the dye. The heat and pressure cause the dye to sublimate and embed into the material’s surface.

6. Maintaining Your Sublimation Printer

- Regular Cleaning: Keep your printer clean to ensure optimal performance. This includes wiping down surfaces, cleaning the print head, and ensuring no dust or debris interferes with the printing process.

- Ink Management: Monitor your ink levels and refill or replace cartridges as needed. Using genuine inks recommended by the printer manufacturer can prevent clogs and maintain print quality.

- Software Updates: Keep your printer’s software and drivers up to date to benefit from the latest features and improvements.

7. Common Issues and Troubleshooting

- Printer Not Working: If your printer isn’t working, check the connections, ensure the drivers are installed correctly, and look for any error messages. Restarting the printer and computer can often resolve minor issues.

- Poor Print Quality: Issues with print quality can be due to low ink levels, clogged print heads, or incorrect printer settings. Perform a nozzle check and cleaning cycle, and adjust the settings as needed.

- Color Mismatch: If the colors on your prints don’t match your design, ensure your monitor is calibrated correctly and that you are using the right color profiles for your printer and sublimation inks.

Conclusion

Sublimation printers are a versatile and powerful tool for creating custom products. By understanding how to choose the right printer, mastering the printing techniques, and maintaining your machine, you can achieve professional-quality results. Whether you’re starting a new business or expanding an existing one, sublimation printing offers endless possibilities for creativity and innovation.